CNC MACHINING, FABRICATION, PLASTIC & TIMBER

CUSTOM CNC ROUTING SERVICES

Who we are

Protocrafts Pty Ltd is an independent design and fabrication workshop based in Baulkham Hills.

We specialise in laser cutting, CNC routing, and custom prototyping — helping local workshops and builders with overflow work, one-off components, and short-run production.

With strong engineering and CAD/CAM expertise, we deliver precise, ready-to-install parts with reliable turnaround, clear communication, and hands-on collaboration.

We focus on quality over volume, building trusted partnerships rather than chasing mass production.

Signage Display

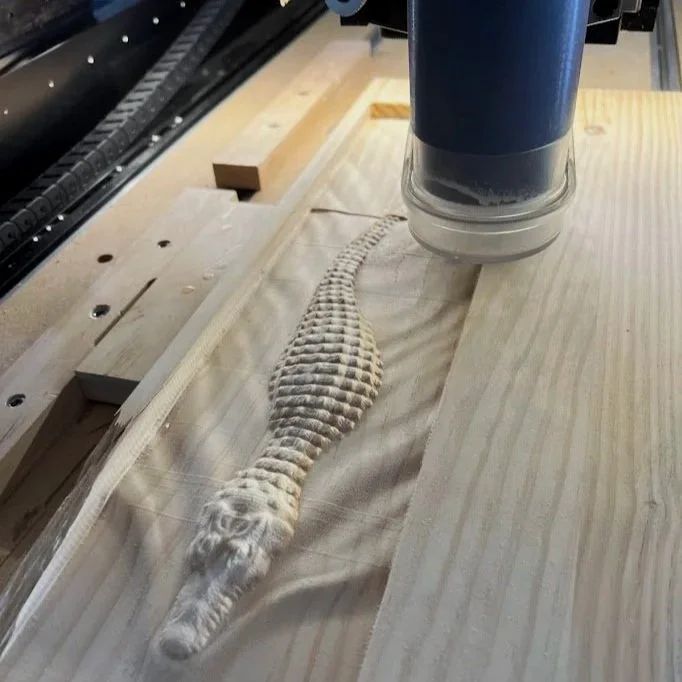

CNC Engraving Wood

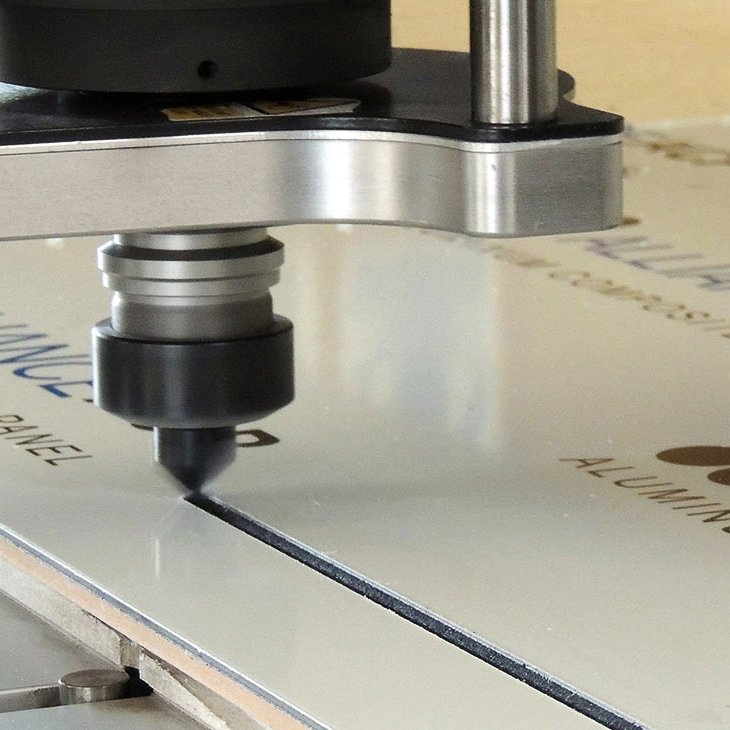

V Grooving ACP

3D Cut Out Router Lettering

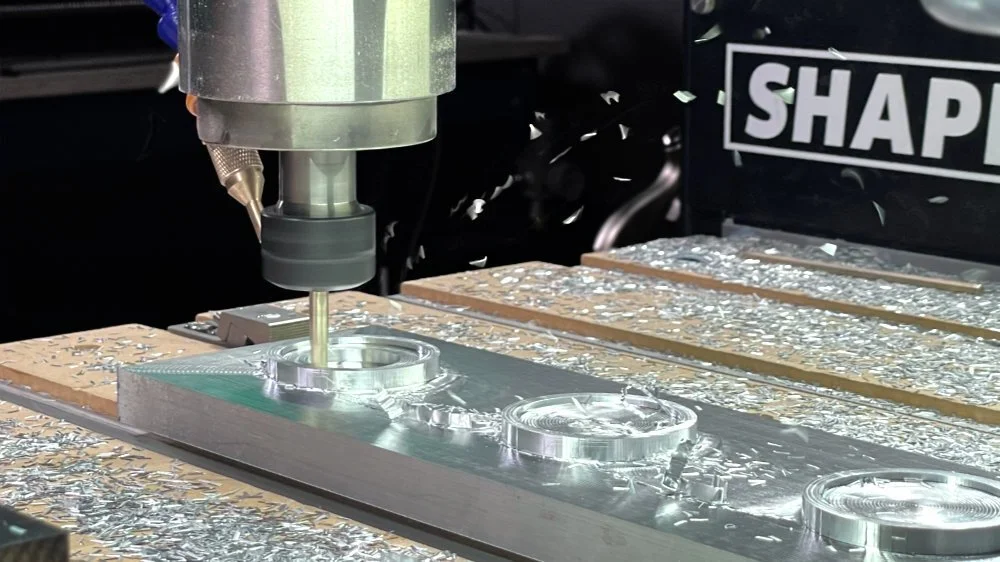

Custom CNC Cut Outs

CNC Repetitive Cutting

Equipment & Capabilities

-

Our CNC router delivers precise machining for timber, plastics, foams, and light metals. With a working area of 1200 × 1200 mm, it’s ideal for producing cabinetry panels, decorative screens, jigs, templates, and prototype parts.

-

Our CO₂ laser cutter offers exceptional precision for cutting and engraving a wide range of materials including wood, acrylic, leather, and composites. With a 900 × 600 mm working area, it’s perfect for signage components, engraved panels, templates, and decorative work.

Designed for fine detail and clean edges, it’s ideal for custom branding, labeling, or intricate pattern work. -

Our SLA and FDM 3D printers enable high-precision prototyping and custom part production.

SLA printing delivers ultra-fine detail and smooth surface finishes — ideal for small components, enclosures, and visual prototypes.

FDM printing provides strength and versatility for functional parts, jigs, and tooling applications.

Using Fusion 360 and Autodesk Inventor, we can model, slice, and print accurate parts that integrate perfectly with CNC- or laser-cut components. Perfect for rapid prototyping, fit-testing, or producing custom hardware that needs to move from concept to reality fast.

-

Our fabrication process begins with precision design. Using Fusion 360, Autodesk Inventor, we create detailed 2D and 3D models that translate directly into machine-ready toolpaths.

This integrated workflow ensures every CNC, laser, or 3D printing job is dimensionally accurate, material-efficient, and production-ready.

Whether you provide finished drawings or rough concepts, we can prepare, optimise, and manufacture your parts — ensuring a seamless transition from design to fabrication. -

Our fiber laser marking system provides permanent, high-contrast engraving on metals and engineering plastics. It’s ideal for serial numbers, logos, identification plates, and precision component marking.

The process leaves a clean, durable finish that resists wear, making it perfect for industrial tags, machine parts, or custom branding. -

Our workshop is equipped with a complete range of power tools, hand tools, and finishing equipment to support precise assembly and final detailing.

From sanding, drilling, and routing to accurate clamping, measuring, and surface preparation, every project is handled with care and control.

Free Estimate

Please reach out to discuss your project or idea.